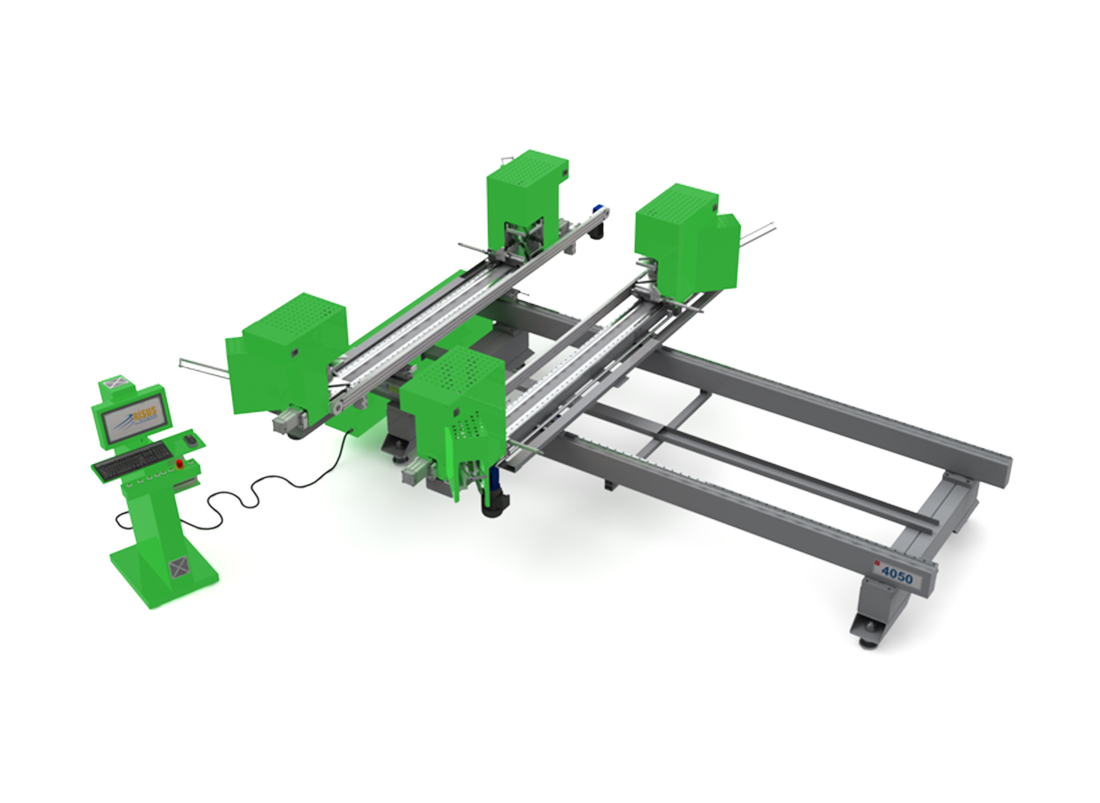

It is a cnc machine with 3 axes servo motor control, designed for 90° welding of pvc door&window profiles. Control of the machine is done with touch-operated PC with Windows operating system and axis movements are provided by high technology motion control systems. Thanks to PC control technology, data transfer with all windows and optimization programs is very easy. The dimensions of the frames welded with the servo motor and ball-screw motion transfer technology used and the accuracy of 90° angle is very high. Welding of coated and uncoated profiles (0.2 mm- 2 mm) is possible. The mold changing system is very practical. Coiled teflon replacement system in roll form makes easy and economical teflon replacement. It is very simple to introduce pvc frames to the machine with barcoded or manual data entry. Thanks to the special software of our company, warning and error messages are displayed on the control screens of this line and the error in the system can be solved easily by the operator. It is possible to weld all window combinations.

.jpg)

.jpg)

.jpg)

.jpg)