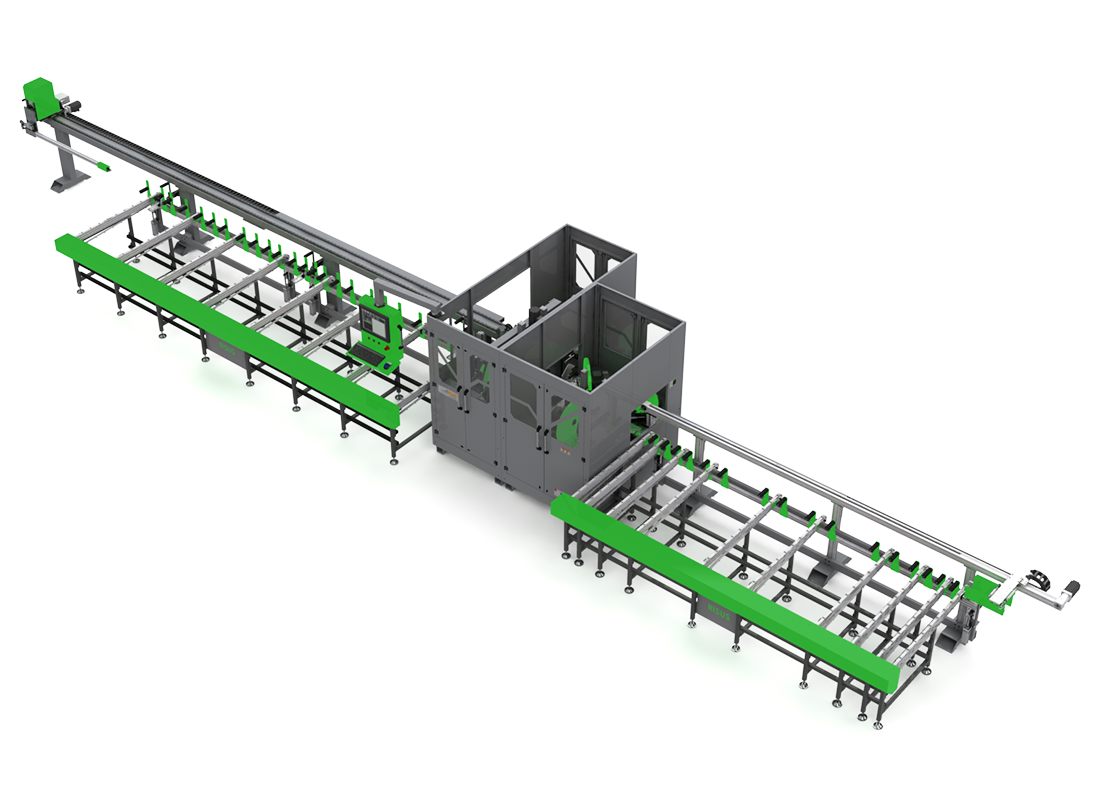

It is a 9 axis automatic line with servo motor control designed to realize all machining and cutting operations of pvc door&window profiles with high accuracy and capacity integrated with window design program. It consists of 4 different stations. These; the feeding unit, the machining unit, the cutting unit and the outlet unit. At the RMC-501 Machining and Cutting Center, the operator only loads the profiles and picks up the finished product. Control of machining and cutting center is done by touch screen PC with Windows operating system and axis movements are provided by high technology motion control systems. Thanks to PC control technology, data transfer with all windows and optimization programs is very easy. The servo motors, ball-screw and rack-pinion motion transfer technologies used in all units have high product accuracy.

Feeding unit, min. 800 mm and max. 6500 mm profiles can be loaded in length. It has 9 profile loading capacities.

The machining unit consists of a ring system with 360° turns with 7 tools on it. Cutting unit; It consists of 3 different saws positioned at 45°, 90° and 135° degree and is supported by a waste discharge conveyor to remove the generated waste parts from the system. In the outlet unit, the machined and cut profiles are transferred onto the conveyor, and the labels obtained from the barcode system are pasted onto the finished products by the operator, and the flow of each finished profile is determined. Thanks to the special software of our company, warning and error messages are displayed on the control screen and the error in the system can be solved easily by the operator.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)